HK Laser & Systems

Laser cutting

HK Laser & Systems: Precision Laser Cutting Technology

HK Laser & Systems, founded in South Korea in 1990, is a world leader in the production of high-precision laser cutting systems, developing advanced solutions for the sheet metal processing industry. With a design based on rigorous structural analysis, HK offers ultra-light, high-performance laser machines, as well as bending, welding, deburring, and automation solutions.

Zinetti Technologies: Exclusive Partner for France and Italy

Zinetti Technologies is the exclusive distributor of HK Laser & Systems for the French and Italian markets, providing customers with technical expertise, specialized support, and tailored solutions to seamlessly integrate HK machines into their production processes. With in-depth industry knowledge and a dedicated after-sales service, Zinetti Technologies is a strategic partner for companies seeking innovation, reliability, and continuous support.

Innovation and Reliability in Production

HK stands out for its continuous investments in research and development, ensuring that its machines are always at the forefront of technology. Its laser cutting solutions offer:

-

High precision and speed, thanks to advanced control systems

-

Optimized energy consumption, to reduce operating costs

-

Maximum reliability, with rigid structures and high-quality components

-

Intelligent automation, to improve productivity and reduce waste

A Technical Support of Excellence

Thanks to the partnership with Zinetti Technologies, customers in France and Italy benefit from:

-

Fast and specialized assistance

-

Tailored technical expertise to choose the best solution

-

Integration with software and automated systems to optimize production

-

Immediate availability of spare parts and a responsive after-sales service

The Mission of HK Laser & Systems

With over 2,000 laser systems installed worldwide, HK is committed to providing the best solutions for sheet metal processing, developing strategic partnerships that ensure shared success.

Thanks to its global presence and collaboration with Zinetti Technologies, HK brings laser cutting excellence directly to French and Italian companies, with a reliable, professional, and cutting-edge service.

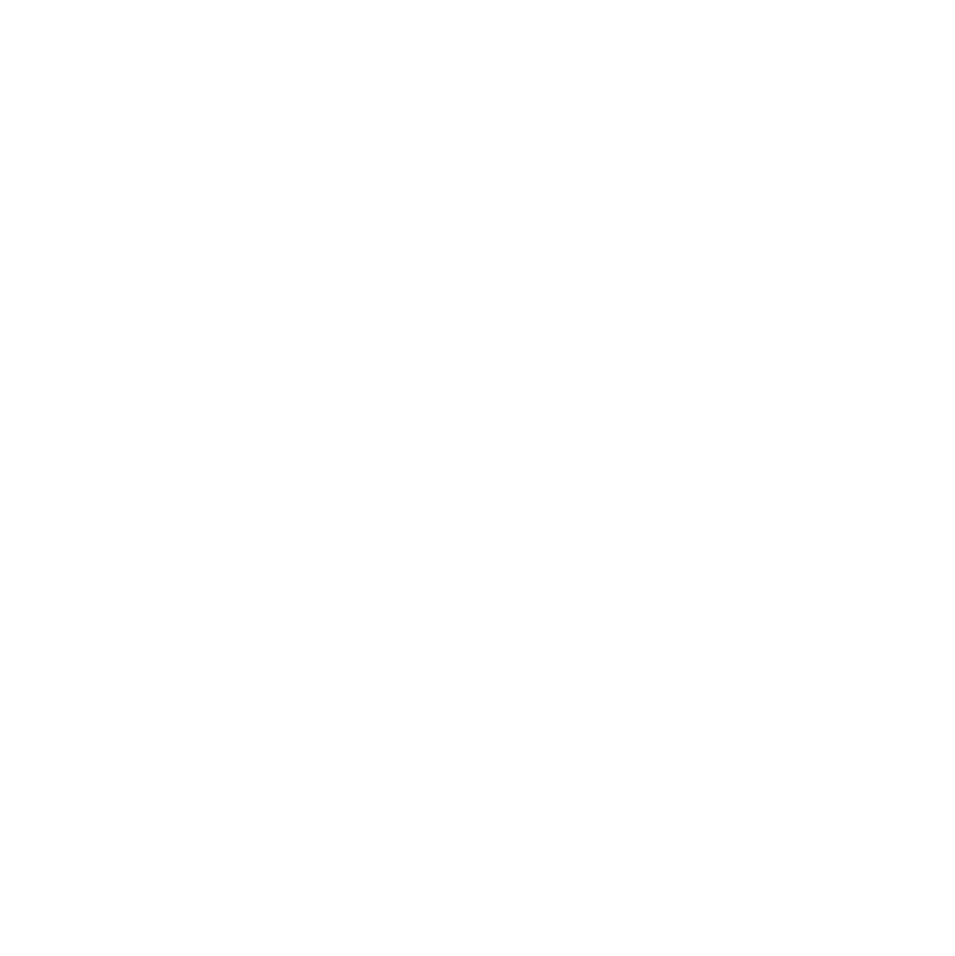

RS3015 FIBER

Integration of Cutting-Edge Laser Technology

-

High-dynamic motion control (2.5G)

-

Easy table access thanks to a fully opening front door and a side door

-

Compact design with minimal floor space requirements

-

Significantly reduced vibrations, thanks to a high-rigidity main frame

-

Integrated LASER source within a climate-controlled cabinet

-

High productivity and quality, ultra-precise performance

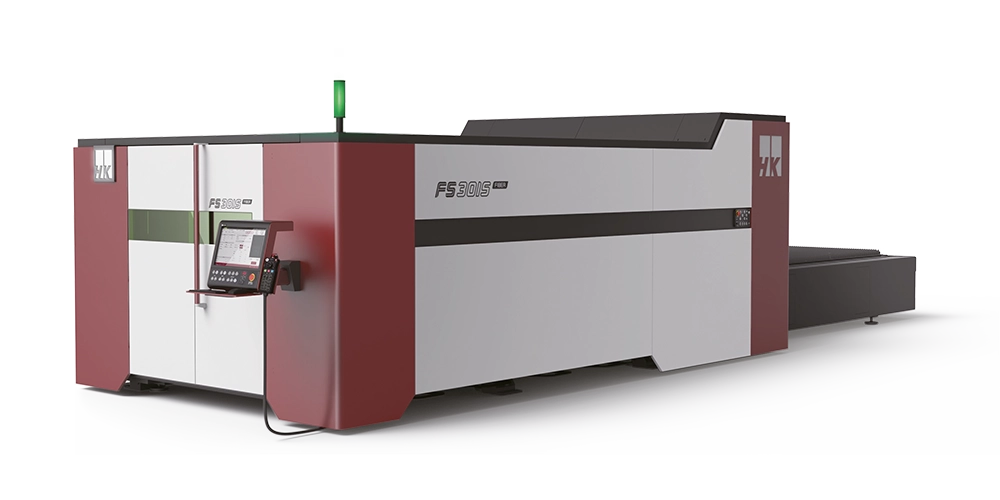

FS SERIES FIBER

High-Performance Standard Design

-

Dynamic motion control (2.0G)

-

High-rigidity main frame and cutting bridge

-

Various table size options (max. 8m x 2.5m)

-

High-quality, high-performance CNC, LASER source, and cutting head

-

Integrated LASER source in a climate-controlled cabinet

-

Digitalized monitoring system based on Industry 4.0

FL3015 FIBER

Top-of-the-Line Side-Door Model, Optimized for Workshops

-

High-rigidity main frame and cutting bridge

-

Easy table access with a wide-opening automatic door

-

Optimized for cutting various types of materials

-

Flexible layout to adapt to your workshop

-

High precision and quality

-

Integrated LASER source in a climate-controlled cabinet

-

Optional module for round tube cutting

FE SERIES FIBER

Standard Design Combining High Performance and Efficiency

-

Dynamic motion control (2.0G)

-

High-rigidity main frame and cutting bridge

-

Various table size options (max. 8m x 2.5m)

-

Folding door and ladder structure for easy access

-

Reduced operating costs through optimized cutting parameters

-

Strategically optimized model combining profitability, functionality, and practicality

HD SERIES FIBER

Cost-Effective Model with Excellent Price-Performance Ratio

-

High-rigidity main frame and durable cutting bridge

-

High-performance, user-friendly FSCUT 8000 controller

-

Full protective cover with CE-compliant safety light barrier system

-

Dual-height table with simultaneous exchange system

-

Dust collection system with automatic cutting area recognition

-

Precision proportional valve for high-pressure cutting

-

LANTEK offline CAD/CAM software included as standard