Lissmac

Deburring and grinding machines

LISSMAC has revolutionized sheet metal processing by developing its own series of machines, consisting of brushing, grinding and deburring machines, and is now one of the market leaders in this field. The machine technology has received several awards for innovation, and sets new standards in sheet metal processing. The simultaneous processing of outer and inner contours is unique in the market and extremely efficient. Whether removing oxidized layers, deburring or grinding, LISSMAC equipment guarantees extremely efficient processing times.

LISSMAC automates processes for our customers with the goal of achieving maximum productivity and cost-effectiveness. To this end, we bring together the experience and expertise of our business sectors and are thus able to provide complete integrated solutions from a single source. Lissmac offers deburring solutions for every need ensuring maximum effectiveness and excellent results in sheet metal processing. Such outstanding results can be achieved by deburring and rounding edges on both sides and one-sided grinding and deburring of cut parts with punching, laser, waterjet, and plasma tools. For a high quality surface finish in both dry and wet satin finishing/deburring, Lissmac offers products that can be configured to specific requirements.

SMB

SINGLE MACHINING CYCLE FOR BOTH SIDES

In the dry machining process, machining on both sides of the cutting edges (inner and outer contours) takes place in a single machining process. Synchronous machining on both sides provides maximum productivity in our customers' production process. The machining principle of LISSMAC's systems ensures optimal tool utilization across the entire machining width, since the workpiece is always machined transversely to the feed direction. LISSMAC's plant portfolio includes three SBM series of machines. Depending on the production task or sheet metal thickness, the M, L or XL series are used. These machine models differ in the number of tool assemblies for processing.

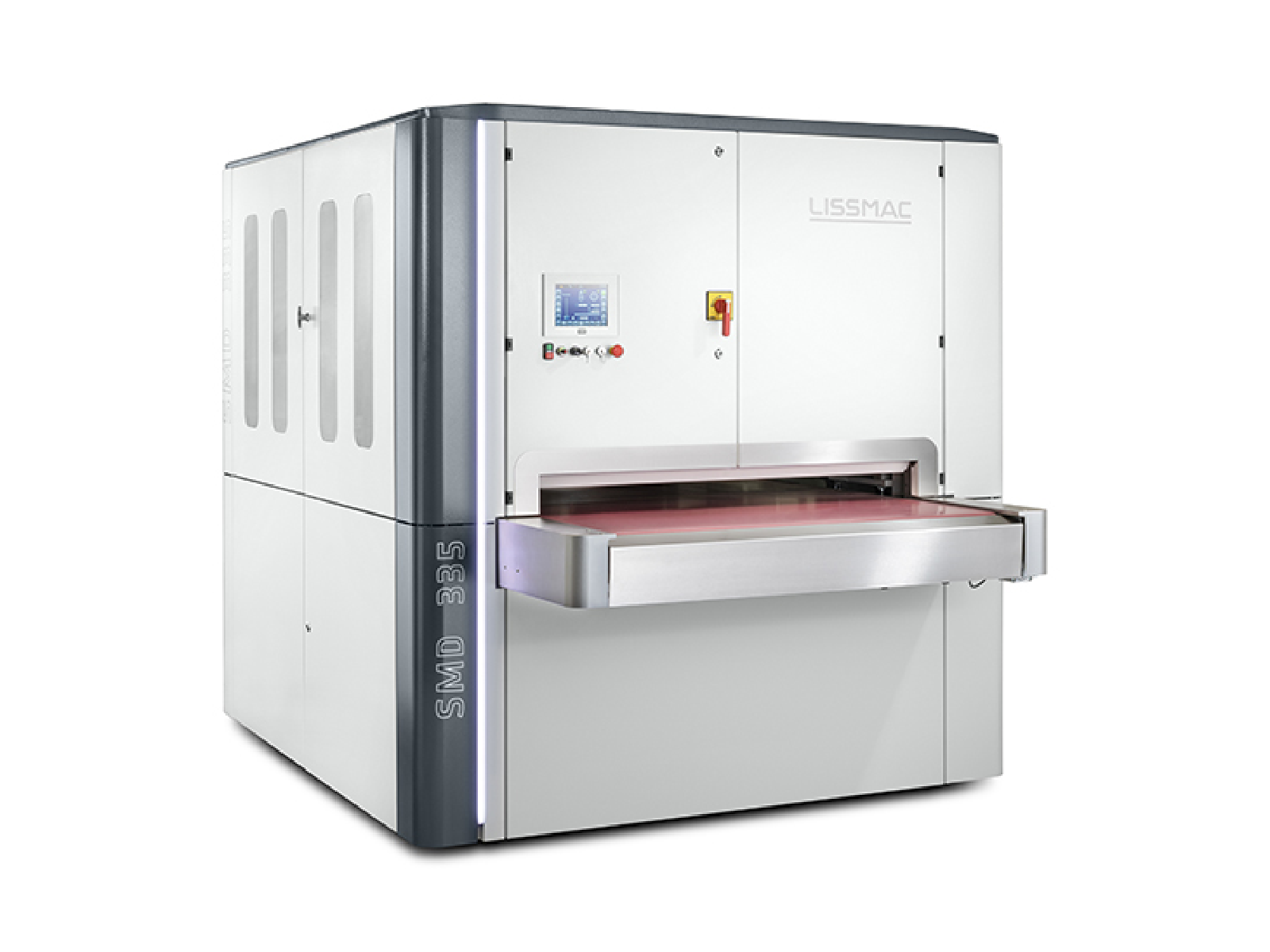

SMD

SMD: DRY MACHINING - ONE-SIDED

These basic configuration machines offer excellent machining results in surface finishing and sheet metal deburring. They are distinguished by low tooling costs, ease of use, and excellent value for money, resulting in faster payback times.

SMW

SMW: WET MACHINING - ONE-SIDED

LISSMAC SMW 5 series sanding machines set new standards for perfect surface finish in wet sanding. SMW 5s built on a modular principle can be custom configured to the customer's needs and are characterized by low tool costs, ease of use and excellent value for money, and the resulting faster payback times.